It takes more than a good idea to create a good shoe

Idea

But at the same time, a very good idea is still needed as a starting point, a springboard and finally for the realization of a good shoe. It is not easy to explain where and how the ideas needed to create a shoe come from. Sometimes they arise from a specific need, sometimes from some kind of example, but always the initial idea draft is followed by thorough work, during which it becomes clear whether the idea could even become a thing or not. Because it may happen that the primary idea is cool, but not at all practical. Or beautiful, but too difficult to implement. Or there are no suitable materials available for him. Or the implementation is too complicated, expensive, unsustainable, etc

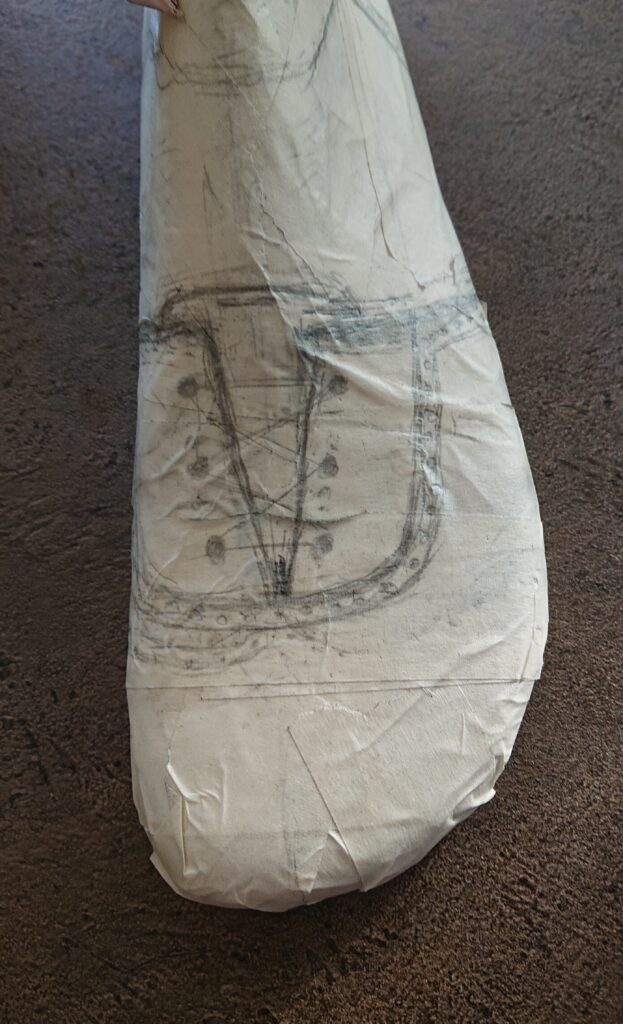

When the idea finally exists and seems feasible, it must be drawn on the slats and all nodes, materials and execution methods must be thought through and established. Where are the seams and cuts, how are they done. What materials – reinforcement, upper and sole materials – are used, how problem and bottlenecks are solved, up to what color and how thick a thread it is sewn with, and what types of hooks, hooks, buckles, etc. are used.

Last

You can’t get No(N)s lasts from the store, they are created just for us, according to our drawings, measurements and requirements. The process took more than a couple of years and will continue until we are completely satisfied and do not need to add or change anything.

When creating a last, it is extremely important to determine for whom, i.e. for which foot, the last is intended.

It is not possible to create a last suitable for everyone. There is a saying in Estonia that translates as “if one thing suits everyone, it suits nobody”. So our last was made to be suitable for No(N)s creators as well as for many who had not yet found their ideal solution – one with a narrow heel, a wide toe part that is wedged but not curved and has a straight but not a protruding big toe. Such a foot, which is rather of medium width and of medium or slightly lower height.

To our somewhat surprise, however, it turned out that shoes made according to this last also fit wider and higher feet than expected, and even slightly narrower and lower feet. It certainly helps that in the case of our models, we try to ensure, in addition to the good fit of the shoes, that they are adjustable to the greatest extent possible.

Model and cut

No(N)s aims to offer beautiful, comfortable, sustainable and well-wearing footwear. This presupposes what? Good ideas (see the first paragraph) and the resulting good model with a good cut. Good execution, of course, but more on that later.

Since a good fit and stability are extremely important to us, the cut of the model must also allow this. Hence one of the reasons why we use quite a lot of classic techniques and ideas in our models – if something has remained unchanged or little changed in history for a long time, there is usually a reason for it.

Example: Why are shoelaces still in use, even though zippers, velcro and rubber bands have also been invented?

One possible answer – the rubber band stretches out over time and doesn’t work anymore, the velcro wears out, gets full of mud and doesn’t hook anymore, the zipper wears out and falls apart and doesn’t fit everywhere. Laces, on the other hand, allow for easy adjustment and can be exchanged for new regular laces, rubber bands, or emergency cords, wire or cable ties. Of course, this does not mean that rubber bands or velcro or zippers should not be used, but as a thought exercise it is sometimes worth thinking about where certain things/techniques/solutions come from and why they persist.

Another example: why some shoes have a seam on the toe, i.e. why is the toe piece separate?

One possible answer – it saves the leather and allows you to use smaller pieces and choose them in the desired thickness and quality (eg thicker and stronger toe and softer sides). Whereas the seam is classically placed so that it does not hinder the movement of the toes. Of course, the beauty factor also counts. But historically, beauty has mostly gone hand in hand with practicality…

The model is usually created on a last, after which this 3d form must be converted into a 2d pattern, taking into account all seam and other allowances, marking all holes, joints and seams, and so on. Patterns are needed for the uppers as well as for all other details, from the lining to the filling and reinforcement materials and the sole. When it’s all ready, one can start cutting out the details and then put them together.

Leave a Reply